Latest News

Choosing the Best Flux Materials for XRF Fusion Sample Prep

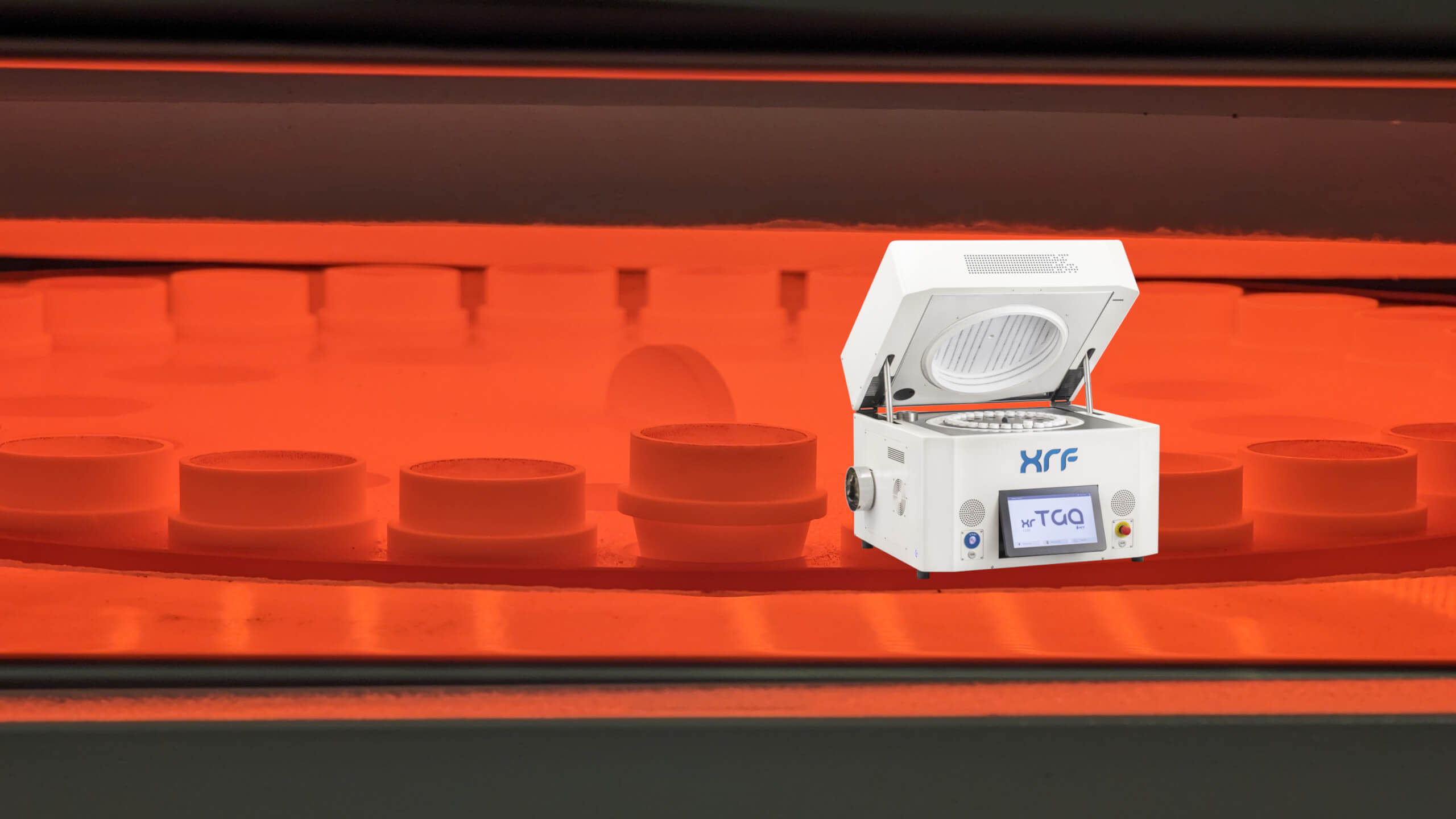

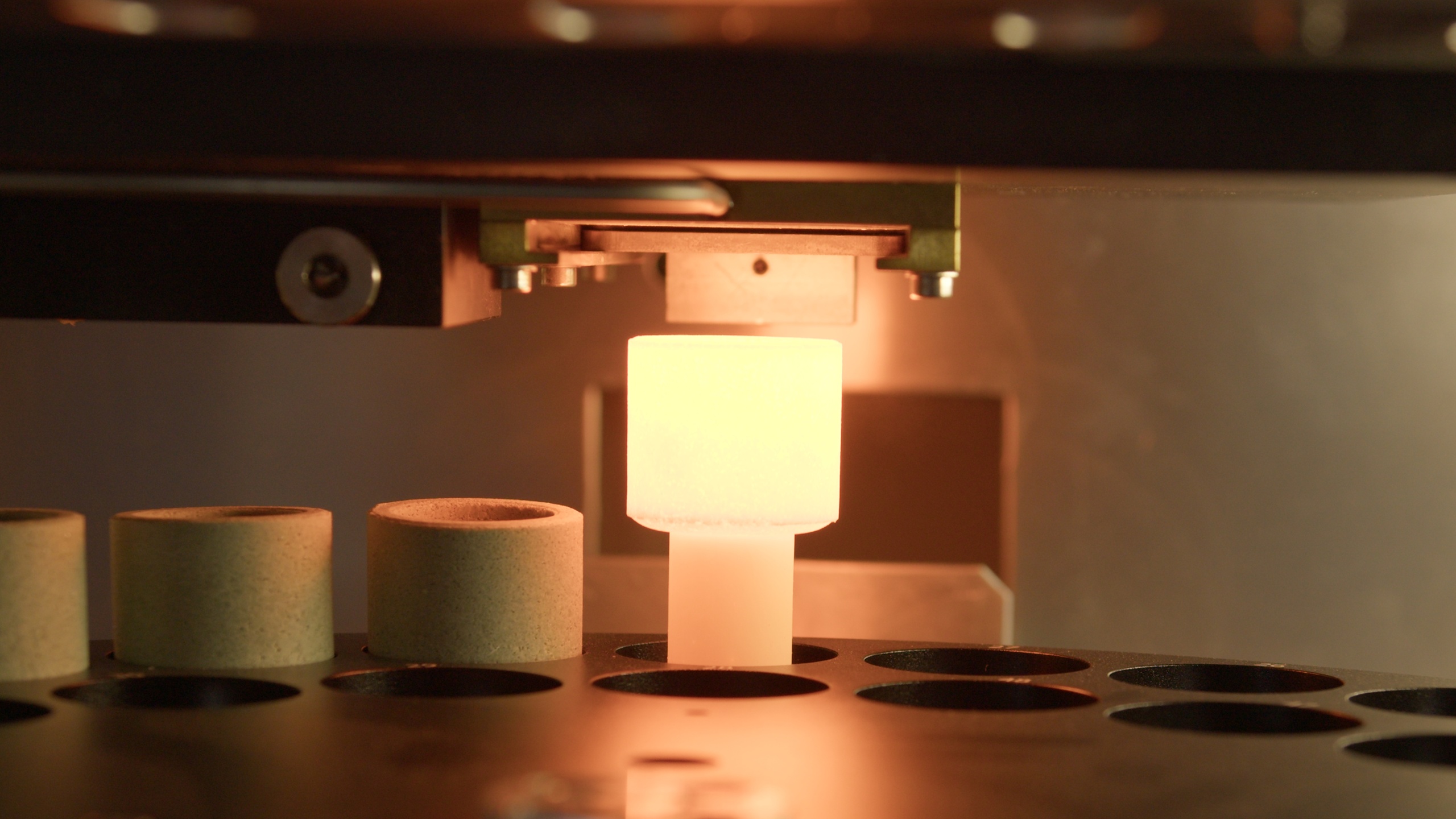

Fusion is an effective way of converting complex solids into homogeneous glass beads during XRF fusion sample preparation, yet the success of this step depends heavily on the chemistry of the flux materials involved. The behavior of flux materials like lithium metaborate, lithium tetraborate, and their mixed formulations directly shapes bead clarity, melt viscosity, and the completeness of dissolution. Because sample matrices vary widely in acidity, mineralogy, and oxide composition, recognizing how different fluxes respond in the melt helps analysts avoid issues like crystallization, bubbles, or undissolved grains. Such a connection between flux properties and matrix requirements makes flux selection a more predictable and informed part of producing high-quality fusion beads for XRF

...

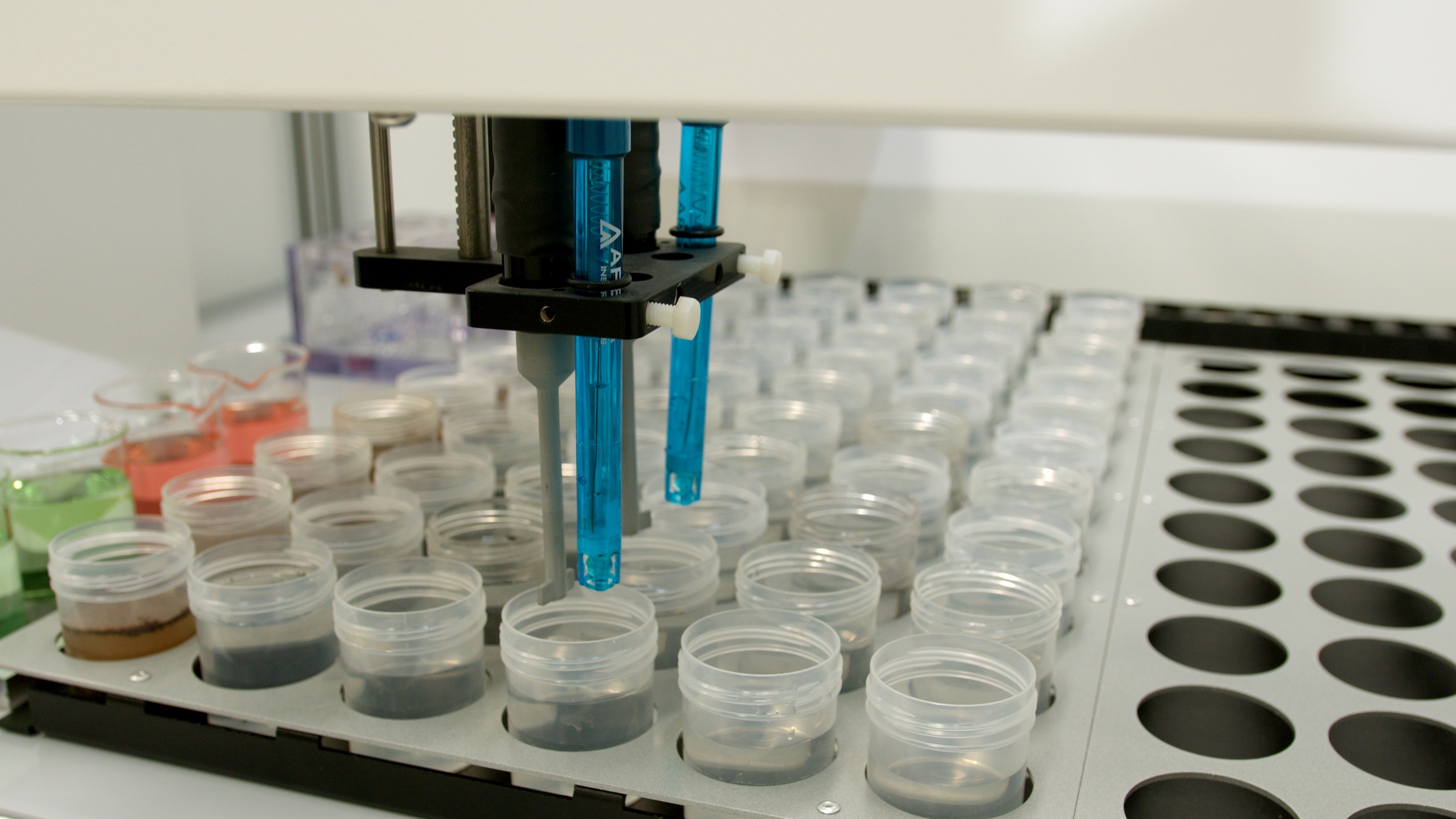

Automation in Pulverising: Streamlining XRF Sample Preparation

The quality of pulverising can determine the precision, stability, and overall reliability of the measurements from X-ray Fluorescence (XRF) analysis, making it a critical step in sample preparation. This stage directly influences how uniformly a material interacts with the X-ray and how confidently laboratories can compare results across batches. If grinding is performed manually, variations in technique, cleaning, and handling can influence the final particle size and introduce sources of error, which is why automation can make such a meaningful impact. It can remove inconsistency and support a more efficient and reliable XRF workflow.

Why Pulverising Quality Directly Impacts XRF Results

A sample’s physical state has a direct influence on how it re

...

Choosing the Ideal Fusion Flux for Consistent XRF Sample Preparation

Consistent, high-quality XRF results rely on far more than just the performance of the spectrometer. The accuracy of the data begins with the way the sample is prepared. Fusion XRF sample preparation is a reliable method for generating reproducible data from oxide, mineral, and geological samples, as it converts powders into homogeneous glass beads that minimize particle-size and mineralogical effects. At the centre of that process lies the fusion flux, a borate-based chemical reagent that lowers the sample’s melting point and enables complete dissolution during fusion. Its chemistry, purity, and handling determine whether the sample fully dissolves and how uniform each bead will be. Selecting the right fusion flux is therefore a critical step in ensuring consistent analytical p

...