Platinum Products for Crystal Growth

Crystals grow as ions and molecules add to the pre-existing lattice structure, which extends in a repeating pattern in three dimensions. This natural process has been simulated and recreated in laboratory conditions to obtain single crystal metals, semiconductors, and synthetic gemstones for a raft of application areas. Manufacturers generally use one of two techniques to encourage crystal growth: the Bridgman-Stockbarger method; or the Czochralski method. Each of these has its advantages and drawbacks, but a unifying difficulty for all crystal growth techniques is the acquisition of materials capable of withstanding difficult process conditions.

Platinum products are widely used for crystal growth due to their exceptional non-reactivity in the presence of molten materials and process atmospheres. In this blog post, XRF Scientific will outline the Czochralski method and the suitable platinum products for this crystal pulling process.

What is The Czochralski Method?

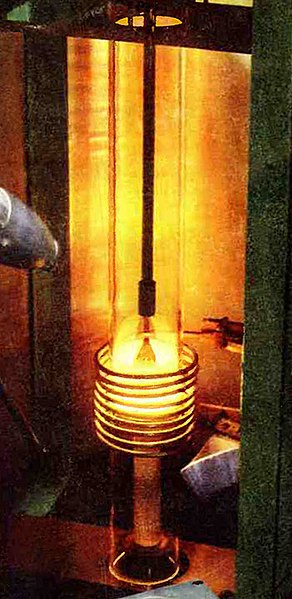

The Czochralski method of crystal growth is over 100 years old and was discovered accidentally by the esteemed chemist Jan Czochralski. It is now the leading method of artificially generating cylindrical ingots of silicon for printed electronics applications. This is achieved by lowering a seed crystal to touch the surface of a molten melt in a platinum crucible and allowing it to reach equilibrium before slowly drawing the crystal upwards. The hydraulic system generally rotates the crystal simultaneously, to ensure homogenous crystal growth in all three spatial dimensions. A typical process might resemble the following:

Platinum Products for Crystal Pulling

Numerous pure platinum products are used in a typical crystal-pulling furnace. This is primarily due to its low reactivity at refractory temperatures. Often, however, oxide crystals are grown from melts that exceed the optimal operating temperature of pure platinum products. Manganese ferrite (MnFe2O4) is a common melt charge in crystal growth, which has a melting point of 1500°C (2732°F). Despite boasting an exceptionally high melt temperature of approximately 1770°C (3218°F), pure platinum products must only be used at maximum continuous use temperatures of 1200°C (2732°F). Anything above this for extended periods will cause the crucible to chemically deteriorate, resulting in cross-contamination and potentially total product failure.

Alloying can help resolve this issue. Platinum products with nominal amounts of rhodium or iridium can reach significantly higher operating temperatures. A typical alloyed crucible with a composition of roughly 90% platinum and up to 10% rhodium can reach a melting point of 1850°C (3362°F). While these temperatures cannot be maintained for extended periods, it can facilitate crystal growth with more challenging melt charges.

Alloyed platinum products are generally harder than the pure product, enabling them to be made from thinner sheets without losing essential mechanical functions. Yet alloying is not a universal solution to the challenges of crystal growth. Cross-reactivity between even trace level minerals in a melt charge and alloys in the platinum lattice can cause chemical degradation, resulting in a process known as leaching. This can contaminate either the grown ingot or the crucible itself. The choice between pure and alloyed platinum crucibles is both chemistry and temperature dependent.

Crucibles are not the only platinum products used in a Czochralski crystal growing furnace. Often the hydraulic stylus that manipulates the seed crystal is comprised of platinum, as are the protective baffles used to limit the outward radiation of heat from the growing ingot. These components are engineered from semi-finished platinum goods like wires, ribbons, and sheets.

Platinum Products from XRF Scientific

XRF Scientific is one of the world’s leading suppliers of platinum products for demanding applications, including custom crucibles and semi-finished goods. Read our previous posts to learn more about choosing a platinum crucible for your application or contact us directly if you have any questions.