Request a Quote

Built with industrial users and large-scale scientific facilities inmind, the XRF Scientific automated macro thermogravimetric analyser (TGA) is a high-throughput solution for a wide range of thermal analysis applications. Our TGA system is based on 30 years’ experience developing precise heating and weighing solutions for applications across the full spectrum of science and industry.

Thermogravimetry sets the standard for thermal decomposition testing for parameters as varied as moisture, volatiles, ash, fixed-carbon, and Loss on Ignition (LOI) content. Our TGA analyser leverages proprietary heating and weighing systems to continuously monitor sample mass changes over time as a function of temperature. User-defined thermal programs can be easily established using an intuitive touchscreen interface, enabling customers to establish different thermogravimetric profiles depending on their materials/phenomena of interest.

Our brand-new TGA adds value to high-throughput workflows with an increased sample capacity and greater temperature capabilities without a significant uptick in cost.

Key Features

- 30 position carousel for larger throughput

- Higher maximum temperature range up to 1100° C

- Highly automated and user-friendly interface

- Fast heating and cooling cycle times

- Fully integrated PC without the need for an external unit

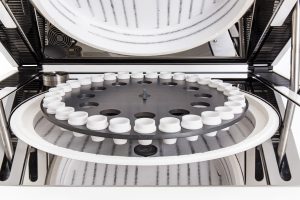

Large Sample Carousel

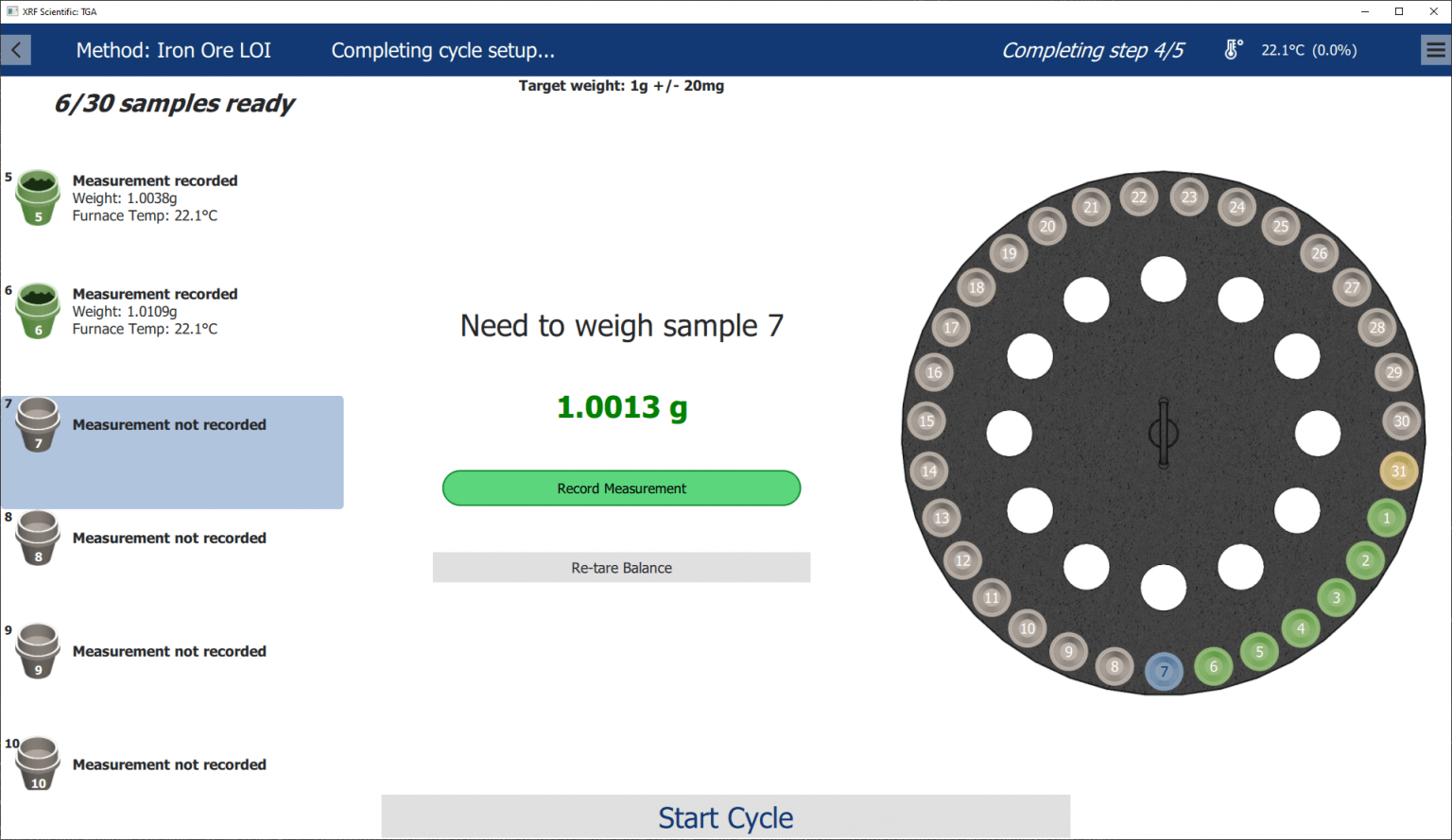

Our large carousel of 30 sample positions plus 1 reference position allows for high throughput in busy laboratories, whilst maintaining a highly efficient heating chamber.

User Friendly Interface

Our PC is built into the TGA, which ensures an external unit doesn’t clutter your bench space. A large touch screen interface is fitted, or alternatively plugin in a keyboard and mouse. Results can be accessed remotely for processing.

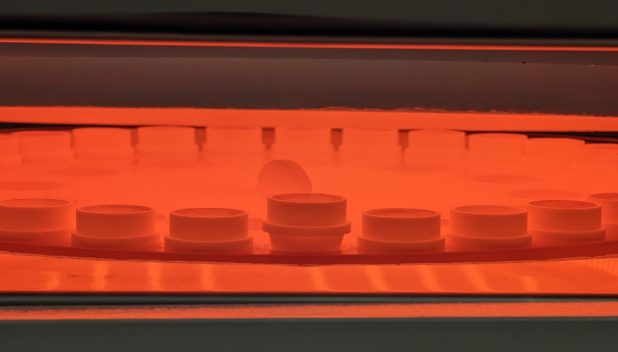

Fast Heating and Cooling Cycles

We understand your laboratory processing time is valuable and you want the results fast. Innovative design features ensure heating and cooling cycle times are quick and accurate, with noticeable improvements over other machines available on the market.

Atmosphere Control

Integrated software-controlled gas switching for experiments requiring inert or reactive atmospheres.

Integrated Ventilation System

Active ventilation keeps the laboratory free from toxic vapours/odours and further improves the cooling process.

Robust and Safe Design

We have applied decades of knowledge in furnace safety into the TGA. The instrument meets stringent CE standards for external touch temperatures and required safety features. The TGA is built to withstand the harshest laboratory environments, with maximum uptime requirements.

Application Types

- Minerals: iron ore mining / steel production, coal, bauxite

- Food: flours, pasta, chocolate

- Construction materials: cement, limestone/lime

- Materials: plastics, alumina, gypsum, agricultural materials, ceramics, pharmaceutical materials

Complying with Standardised methods

- Moisture and ash determination in flour – AOAC 925.10 & AOAC 923.03

- Ash content in thermoplastics – ASTM D5630-94

- Loss on ignition in solid combustion residues – D7348-08

- Loss on mass in alumina – AS 2879.1-2000

- Loss on ignition in cement – ISO 29581-2:2010 / ASTM C 114

- Moisture and loss on ignition in iron ore – ISO 3087:2011 and ISO/TR 18230:2015

- Various AOAC, ASTM, ISO and DIN methods

- And more …

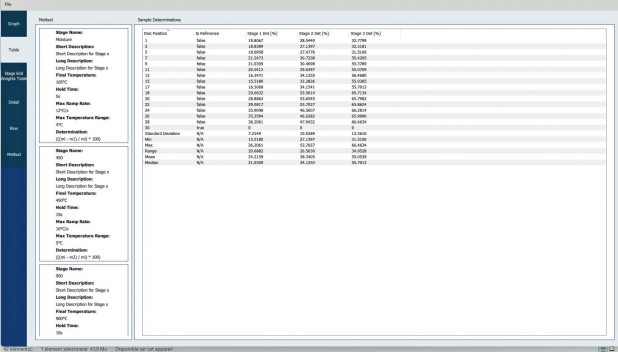

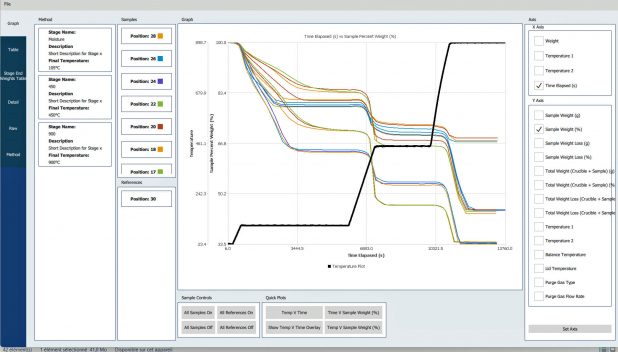

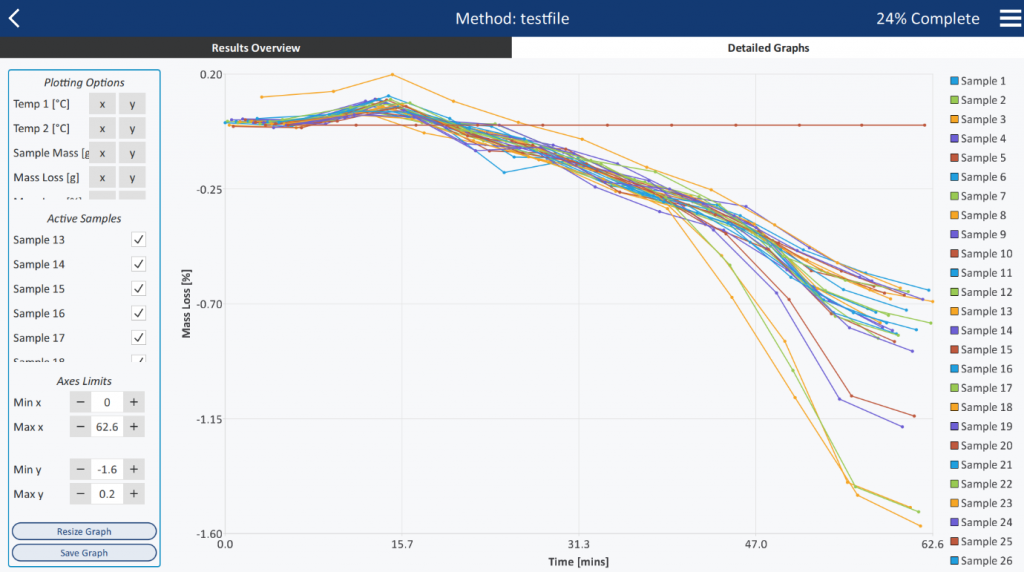

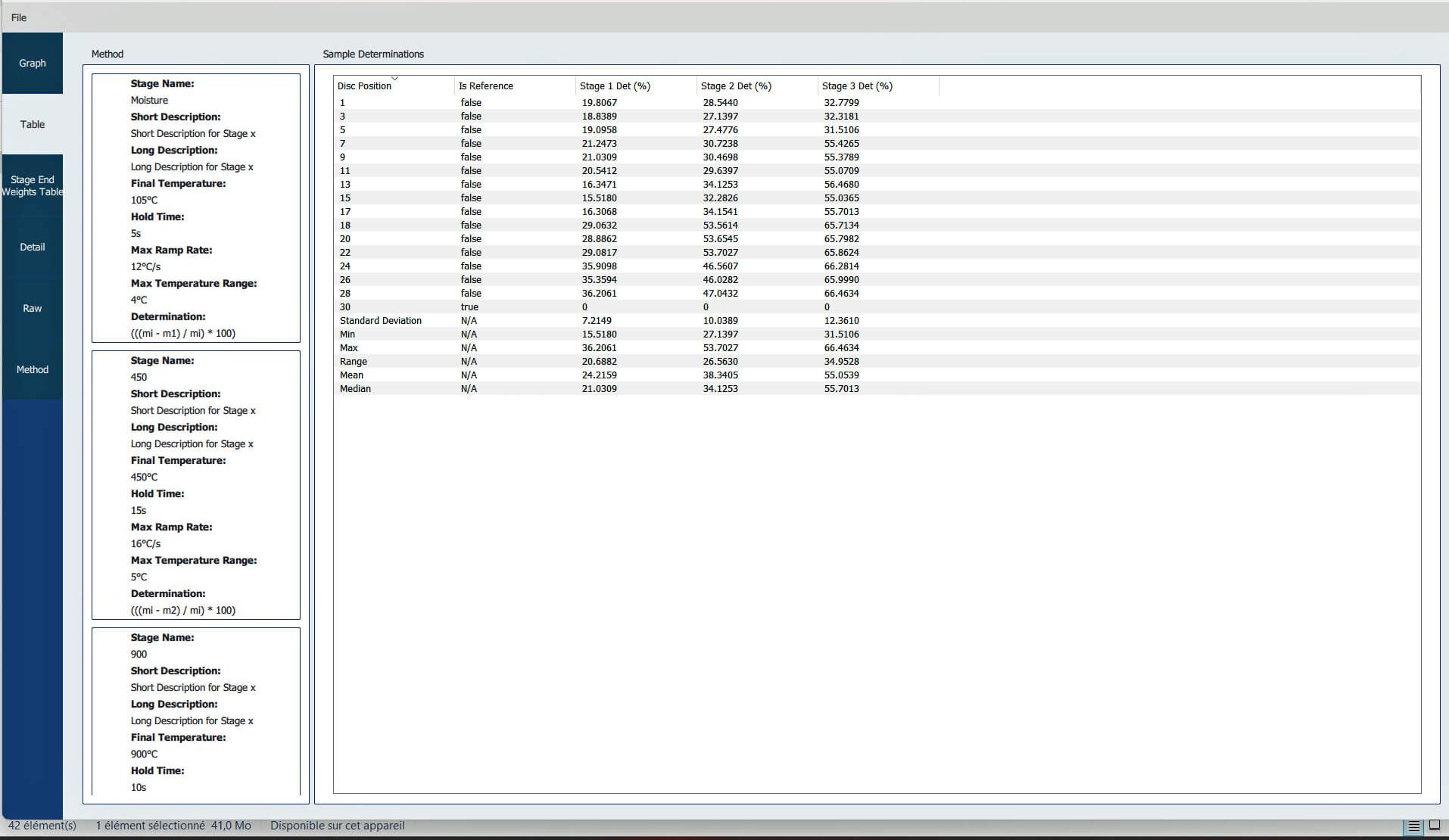

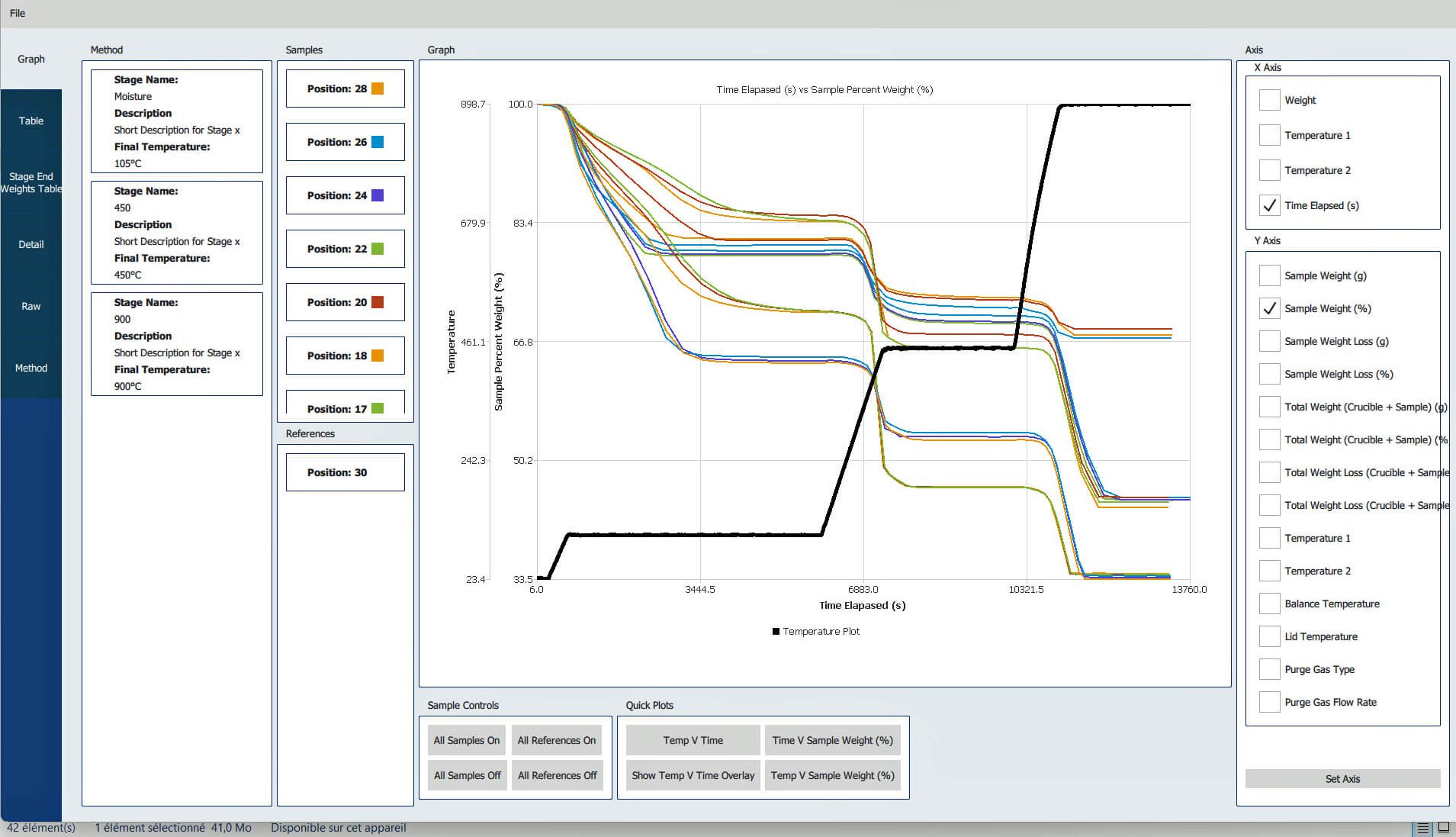

The xrTGA software include a comprehensive set of relevant tools available for parameter settings, diagnostics, real-time data analysis as well as data processing. Analysis software can be accessed on the instrument directly or via a Windows desktop version. Features of the software include LIMS communication, remote access and convenient data export CSV, XML, Excel®.

Instrument Operating Software

Desktop Analysis Software

| xrTGA1100 | |

|---|---|

| Capacity | 30 sample positions plus 1 reference position |

| Sample weight capacity | 0.1 – 10g |

| Weighing precision | ± 1% |

| Resolution | 0.1mg |

| Temperature range | Room temperature to 1100°C |

| Temperature accuracy | ±1°C |

| Temperature precision | ± 1°C at 105°C and ± 2°C at all other ranges |

| Heating rate | 1°C/min to 55°C/min |

| Furnace cooling | Forced air and multi-height lid opening for faster cool down |

| Gas flow rate | 0l/min up to 40l/min |

| Power requirements | 230 V, 50/60 Hz, max. 32 A |

| Dimensions (W x D x H) | 850 x 755 x 675mm H 1100mm with open lid |

| Weight | 165kg |

| Safety and certification | CE marking Operator safety hand switch points for lid closing Integrated ventilation system Over temperature protection safety circuit |

| Accessories for xrTGA 1100 | Product Ordering Codes |

|---|---|

| Crucible 16ml AI203 | 5100201 |

| Lid AI203 to suit Crucible code 5100201 | 5100202 |

| Platinum Crucible 15ml, Pt, 15g | 5100205 |

| Platinum Crucible Liner, Pt, 8g | 5100206 |

| Crucible 30 position tray | 5100207 |

| Stainless steel tongs for removing lids | 5100208 |