Why use grinding aids with your hydraulic press?

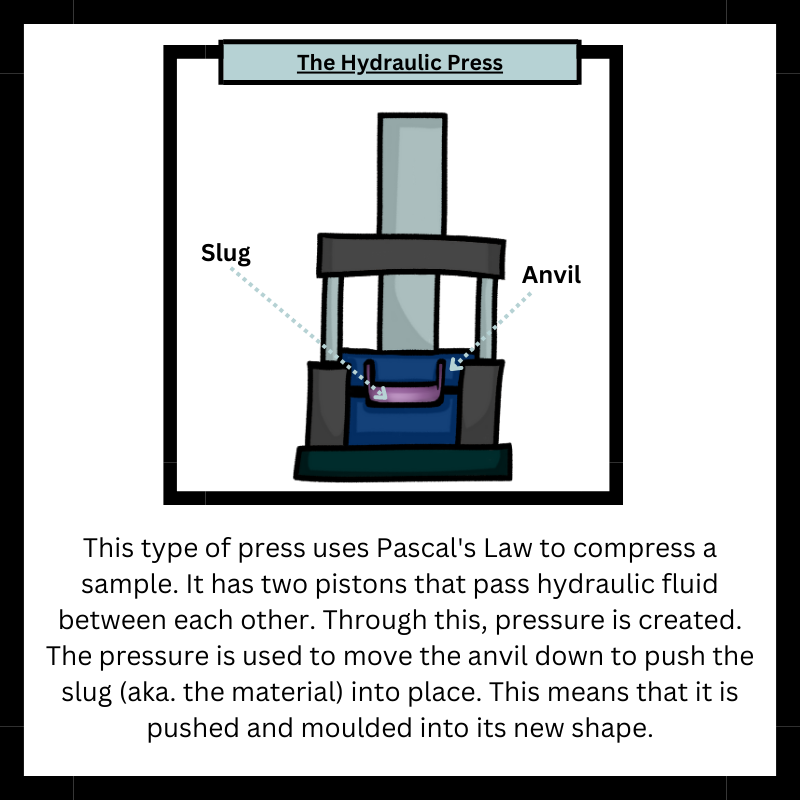

A hydraulic press creates samples of bulk materials through compression. These discs and pellets can be used in X-Ray Fluorescence (XRF) and Inductively Coupled Plasma (ICP) sample preparation to understand the material’s quality and what elements are present.

To continuously reproduce and maintain your results during XRF and ICP spectrometry, you need to focus on your sample preparation before it is used in the pressing equipment. Grinding aids can enhance the effectiveness of grinding during the pelletising process to ensure the pellet or disc sample has the right size distribution of particles.

It is important that you use the best grinding aid when you create your sample. That way you can enhance its homogeneity and decrease the likelihood of sample contamination from other materials.

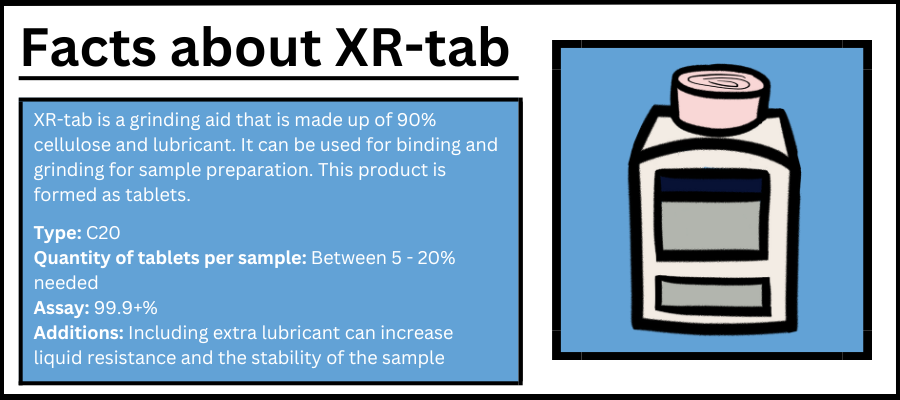

Here at XRF Scientific, we would recommend our XR-tab grinding aid. The XR-tab grinding aid has a composition of 90% cellulose, a molecule that helps a plant’s stem stay robust, and can act as an effective binder.

How to create samples for the hydraulic press

If you want to create a pellet or disc for examination, it is crucial that you focus on the preparation of your sample before it is compacted by the hydraulic press. That way it will be easier to recreate the composition of the materials during analysis.

You follow this process to create a sample:

Grind down the sample to create small particles

Combine the powder with a binder, which can also be found in a grinding aid

Add the mixed powder into a mould

Use the mould in a hydraulic press to compress the sample into a pellet or disc.

The Benefits of using Grinding Aids with a Hydraulic Press

Grinding aids are used at the start of the process to grind down the raw material into smaller particles. This means that they can become a powder that is added to a binder before being placed into the hydraulic press. By creating a set of particles that are small, it can help the overall sample to bond when it is compressed.

Additional benefits include:

Lessening the possibility of sample contamination

Reducing the likelihood of the x-ray being absorbed by the pellet

Enhancing the sample’s homogeneity.

Particle Size and Grinding Aids

A grinding aid helps to consistently recreate the best particle fineness. Some grinding aids have both binding and grinding properties to simplify the pelleting process before the material is placed in the hydraulic press.

When you use a pellet to analyse a material in XRF or ICP spectrometry, it is important that you regulate the preparation process to ensure that the particles of the material are the correct size. Different sized particles will make it harder to bind your sample together and could change the results of your analysis.

During analysis, an x-ray is used on the pellet as the radiation can enter the material. If a sample has larger particles, errors can be created due to a shadow effect. The sample’s consistency may also be disrupted due to the x-ray not being able to completely enter the pellet’s escape depth.

Which grinding aid would we recommend for you?

To make sure that your sample is ready after it is compressed by the hydraulic press, you should use XR-tab as your choice of grinding aid. It has binding properties due to its make-up of 90% cellulose, so it will keep the sample stable in your pressing equipment. This means it is less likely to break as a pellet.

XR-tab is also perfect for grinding a sample that requires more force to decrease its particle size. Due to this, you can grind down tougher materials that you would like to turn into a sample, such as materials for cement.

XRF Scientific can help you find the perfect pressing equipment

Here at XRF Scientific, we understand that having the right pressing equipment and grinding aids can support your analysis. All materials have different atomic structures, so you need to invest in high-performing equipment to ensure your pellets can be recreated.

We suggest that you start with XR-tab as a grinding aid, however we offer other types of pressing equipment for you to consider. Contact us today through our product form to learn more.