A Brief Guide to ICP-MS

Inductively-coupled plasma mass spectrometry (ICP-MS) is an advanced analytical technique that provides trace and ultra-trace level chemical analysis for a wide range of industries. In this blog post, XRF Scientific aims to provide a detailed introduction to ICP-MS, from initial sample preparation to the technology’s various downstream applications.

What is ICP-MS?

A mass spectrum is a form of histogram that represents the elemental fingerprint of a sample. This pattern is plotted by measuring the mass-to-charge ratio of ions versus intensity, which yields detailed information regarding the elemental or isotopic signature of the material under study.

Acquiring this mass spectral data first requires sample material to be ionized via an excitation source. In the context of ICP-MS, the excitation source is an electromagnetically-generated plume of plasma. The temperature of this plasma is enough to ionize virtually any element on the periodic table, laying the groundwork for extremely varied and detailed elemental analysis at trace and ultra-trace levels. For a more detailed breakdown of the working principles of ICP-MS, see our previous blog post: What is ICP Spectroscopy?

ICP-MS Components

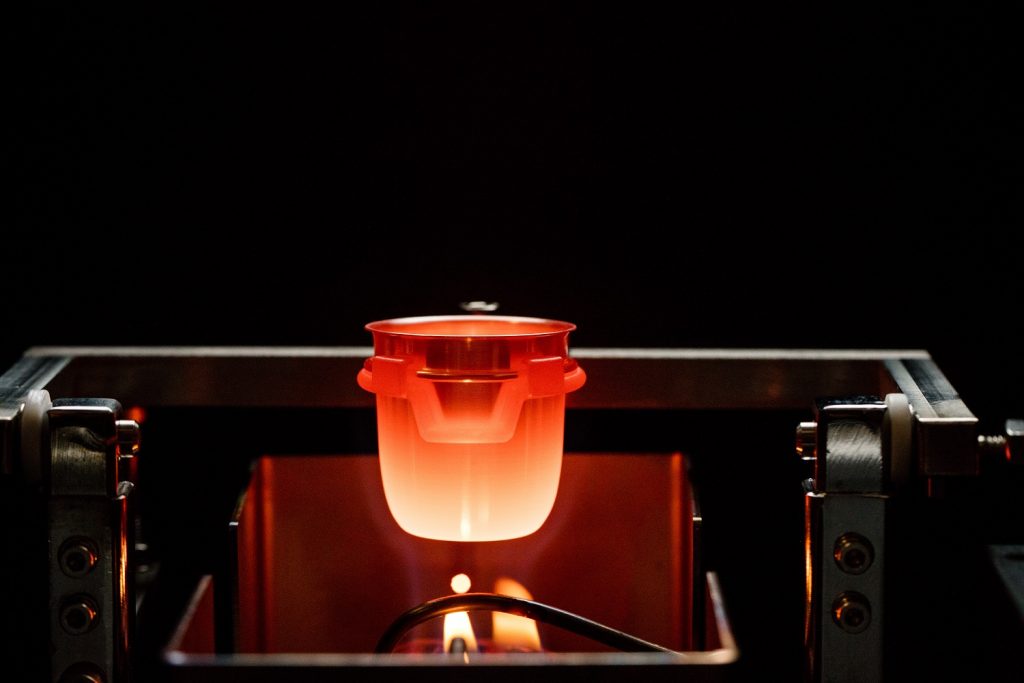

The two chief components in an ICP-MS unit are the eponymous ICP torch and the mass spectrometry unit. The torch usually comprises a radiofrequency coil surrounding several concentric tubes, which deliver argon gas streams for ignition via a Tesla unit. This generates a jet of plasma at temperatures of up to 7000K; enough to ionize virtually any nebulized sample material. Due to these high temperatures, the ICP unit is typically protected with platinum bonnets and torch shields.

Alongside the ionizing component, ICP-MS spectrometry requires an appropriate sampling inlet capable of acquiring ions and segregating them based on the mass-to-charge ratio. This allows the mass spectrometer to generate a detailed mass spectrum to provide fully quantitative elemental analysis at the parts per million (ppm) range. If you would like to learn more about the integrated components in an ICP system, read our post on the Essential Components in ICP Torches.

Applications of ICP-MS

Owing to the broad range of available sample materials, the applications of ICP-MS are extremely varied. It is readily used in mineral and rare earth element analysis, including metal speciation, mining and exploration, archaeological studies, and more. The medical and forensic applications of ICP-MS are likewise growing more diverse, providing the basis for advanced diagnostic processes and forensic analyses. We covered this topic in more depth in a previous post: Outlining Common ICP Applications.

ICP-MS Sample Preparation

Sample preparation is a critical stage of the analytical process for ICP-MS, irrespective of the end-use application. The exact method varies depending on the phase and general composition of the material under test. Liquid samples, for example, may be introduced directly into the unit within an appropriate mixture of an internal standard. This process will not work for solid samples or heterogeneous mixtures, as results may not correspond to the mass spectra of bulk materials.

To ensure the utmost reliability of ICP-MS results with particulate or solid matter, it is best to precede testing with additional sample preparation stages (i.e. grinding, fusion, etc.). This ensures that mass spectral data remains as close to a homogenous representation of the bulk material as possible.

XRF Scientific: ICP-MS Solutions

XRF Scientific is a world leader in the field of sample preparation equipment and consumables for high-analytical testing. We provide a range of solutions for ICP-MS, from fusion fluxes to benchtop fusion machines. If you would like to learn more about the XRF Scientific product range for ICP-MS applications, simply contact a member of the team today.