4 Critical Steps for Precise XRF Sample Preparation

Data integrity in analytical spectroscopy studies is dependent upon the performance of integral components and the method of sample preparation. This is true of both x-ray fluorescence (XRF) and inductively-coupled plasma (ICP) techniques, which analyze extremely low-level optical signals to quantify the elemental composition of samples at the trace and ultra-trace scale.

Ongoing product care and calibration can minimize the potential for error from mechanical variations to negligible levels. This is a prerequisite for spectroscopy applications which must contend with avoidable phenomena such as laser drifting and the spalling of platinum labware. Optimal sample preparation, meanwhile, can be achieved through four critical steps.

Sample Collection and Homogenization

The initial collection of the sample material is largely dependent upon the type of material and the application area. Industrial mineralogical samples can be gathered in bulk sizes, weighing up to 20 kilograms (kg), and run through a laboratory crusher in multiple passes to reduce materials into more manageable pieces. This is a suitable first sample preparation step for rugged applications where samples can be destroyed prior to analysis.

More sensitive samples are typically subjected to non-destructive extraction techniques, where small volumes of material are removed from the surface of the sample using a tool such as a scalpel. This may be too invasive for extremely valuable samples like archaeological discoveries or works of art, requiring innovative extraction tools to remove tiny amounts of surface matter for further sample preparation.

Weighing and Flux Dosing

Whether samples are homogenized in mass, or extracted individually, they must be weighed to establish a reference prior to flux dosing. High throughput sample measurement is best achieved using an automatic system that can eliminate human error and ensure sample uniformity across multiple batches. This initial measurement is then used to inform the amount of flux and additive agents required to achieve fusion and sample formation.

Fusion

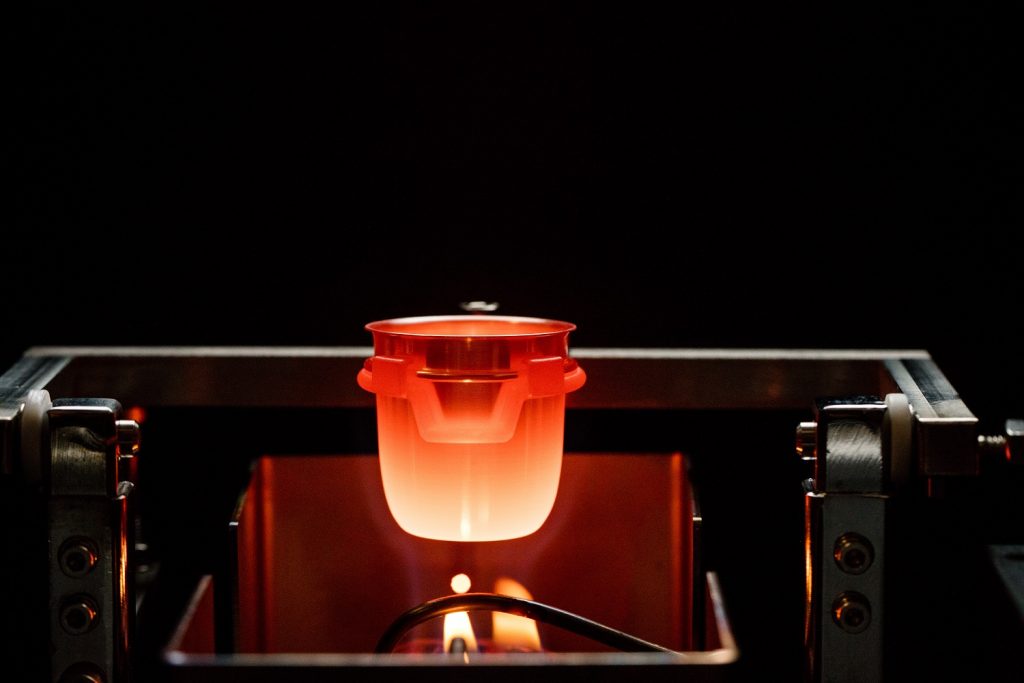

Fusion and sample forming is the final step in XRF and ICP sample preparation, requiring a high-temperature furnace with a specialized cradle. Once the sample has been dosed with the appropriate additives in a platinum crucible it is introduced to the thermal processing chamber, which can reach temperatures of up to 1250°C (2282°F). This causes the eutectic mixture to reduce into a molten slurry, which is agitated by the mechanical motion of the furnace’s cradle.

Forming

Once the pre-defined thermal cycles of the furnace are completed, the cradle pours the molten mixture from the crucibles into platinum molds. In the case of XRF spectroscopy, these molds form the samples into net shapes with near-perfect homogenous representations of the original sample. Heterogeneous liquid samples are contained in beakers prior to nebulization for ICP analysis.

XRF Sample Preparation with XRF Scientific

XRF Scientific was founded to enhance the customer experience of cutting-edge analytical spectroscopy, providing increased productivity, yield, cost-efficiency, and reliability. We offer comprehensive solutions for each of the aforementioned sample preparation steps alongside a robust method development service.

If you would like any more information about sample preparation for XRF or ICP analysis, please do not hesitate to contact us.