Glass Bead Machines for Construction Material Analysis

Construction materials are subject to intense scrutiny from an array of international specifications. Raw materials, intermediates, and finished products must meet pre-defined performance criteria to pass certifications regarding safety and sustainability. If chemical defects are not detected until the end-product stage, significant investment may be required to redress the issue.

X-ray fluorescence (XRF) analysis is widely used in the construction sector to analyze the constituents of building materials and avoid foreseeable costs further down the production line. This process typically involves taking samples of in situ raw materials and intermediate products and processing them through glass bead machines for ultra-precise elemental analysis via an XRF spectrometer.

One of the most pervasively used construction materials worldwide, cement is regularly assessed through XRF analysis to determine the concentration of oxidized compounds such as aluminum oxide (Al2O3), calcium oxide (CaO), and iron oxide (FeO). Undesirable amounts of these materials can alter the functionalities of the end-product and cause components to fail certifications.

This blog post will explore the preparation of cement samples with a glass bead machine for XRF analysis:

Cement Analysis: Experiment Parameters

Prior to electrical fusion of cement powder with a mixture of lithium tetraborate and lithium metaborate flux, the sample first had to be homogenized using the Orbis OM50 jaw crusher. This hydraulic homogenizer can reduce geological solid samples by 35 times its original size with reduced risk of cross-contamination due to the speed and efficiency of the gyrating jaws. A total of 1,250g of powdered sample material was then calcined at 950°C (1742°F) for two hours prior to preparation in the xrFuse 2 glass bead machine.

Samples were then weighed into platinum fusion crucibles and dosed with a lithium borate mixture of 66 – 34 lithium tetraborate – lithium metaborate. Additional oxidizing elements were added to the mixture to protect the crucible from chemical attack via trace amounts of ferrite compounds in the sample.

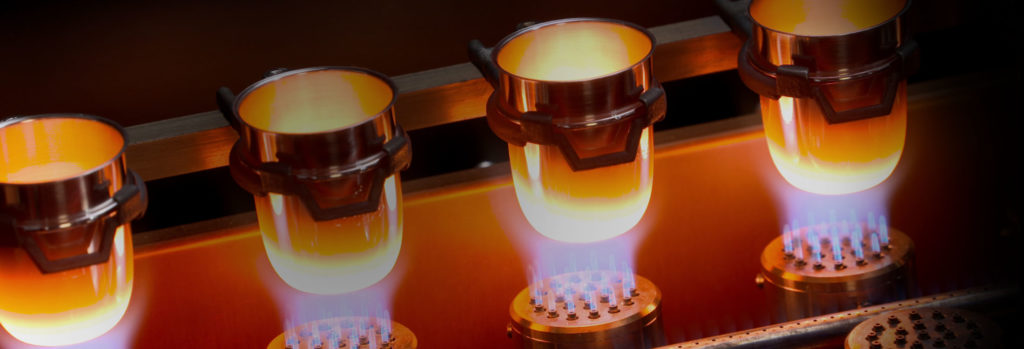

This platinum crucible was then transferred to the cradle of the xrFuse 2 glass bead machine. Fusion times were pre-established, with a pre-melt warm-up to 850°C (1562°F) within 30 seconds and a melt time of 120 seconds at temperatures of up 1050°C (1922°F). The sample was then agitated at this elevated temperature to encourage uniform bonding of sample constituents to flux materials.

The xrFuse 2 glass bead machine then poured the molten sample mixture into platinum molds over a period of 30 seconds and reduced the temperature over several minutes to uniformly cool the material.

The resulting glass beads were used to assess the chemical content of cement samples against reference materials to determine the quality of the material against ASTM C standards.

Glass Bead Machines from XRF Scientific

The xrFuse 2 is a robust glass bead machine engineered to prepare samples at near-perfect homogeneities to provide actionable insights into the quality of construction materials such as cement.

Read about our glass bead machines for XRF analysis of iron ore. Or, if you would like any more information about our glass bead machines, please do not hesitate to contact us.