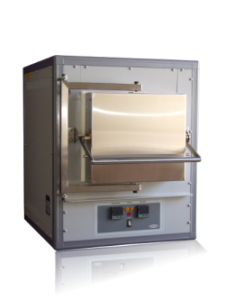

Muffle Furnaces for High-Temperature Laboratory Heating

A muffle furnace is a critical component for high-temperature laboratory heating, enabling samples to be heat-treated at temperatures exceeding 1000°C (1832°F) with low risk of cross-contamination. This is due to the mechanical arrangement of the hearth, which is heated with high-purity metallic elements as opposed to gas burners. These components are fabricated using electrically-conductive metals with high mechanical stability at elevated temperatures.

This article will explore the components of a muffle furnace in more detail.

The Components of a Muffle Furnace

Kanthal wiring is routinely used to fabricate heating elements for muffle furnaces. This iron-chromium-aluminum (FeCrAl) alloy retains its physical integrity at increased temperatures as oxidized aluminum molecules migrate to the wire’s surface and form a protective patina that gives kanthal wires outstanding thermal condu

ctivity. It is an extremely tough material with a melting point of 1500°C (2730°F) and a high degree of malleability, allowing it to be wound into bespoke shapes and embedded into insulators or furnace linings.

Solid-state relays control the voltage of these wire heating elements with additional tempera

ture controllers attached to thermocouples embedded in the muffle furnace. This allows analysts to accurately monitor the thermal conditions of the heating chamber in real-time and adjust it via a digital PID or an optional precision controller.

Refractory furnace linings are used to ensure that these heating elements and controls affect

the process conditions accurately and with good degrees of uniformity. High strength alumina (AlO) or insulating firebricks made of advanced silicon carbide (SiC) are used to wall the muffle furnace hearth, which is constructed in a robust frame of powder-coated steel or aluminum. Additional ceramic fiber insulating elements are used to protect the external superstructure of the muffle furnace and to improve the radiation of heat throughout the heating module.

Certain thermal treatment processes can cause samples to produce potentially hazardous off-gas, or to exude vapors and moisture. Muffle furnaces designed to treat samples and reduce the risk of moisture re-uptake may require integrated air-flow controls and venting components such as fume hoods and exhaust tubes. These can be assisted with integrated fans that serve the dual purpose of equally distributing heat throughout the module and exhausting extraneous gasses or vapors.

Muffle Furnaces from XRF Scientific

At XRF Scientific, we provide two distinct ranges of muffle furnaces for materials testing applications such as gold cupellation and metal assaying. These are distinguished by the arrangement of the kanthal wire elements, which can either be wound or embedded into the furnace lining.

These muffle furnaces are usable at continuous temperatures of 1050 – 1200°C (1922 – 2192°F) with optional overtemperature monitoring to ensure that process temperatures do not exceed operable values for extensive periods.

If you would like any more information about our muffle furnaces, please do not hesitate to contact us.