CS1232 Carbon Sulphur Analyser

Request a Quote

The CS-1232 Carbon and Sulphur Analyser is designed to determine Carbon and Sulphur in minerals and organic materials. The CS-1232 uses a vertical resistance furnace that significantly simplifies the design and makes automation much more reliable. The vertical furnace provides and “airgap” around the combustion crucible inside the combustion chamber. This method of heating prevents any unwanted thermal shocks from cold combustion boats as used in other instrumentation. Even heating and advanced thermal insulation reduces power consumption to less than 15 amperes at temperature.

The instrument includes a 48-position sample changer as an integral part of the analyser which will run unattended and store the analytical results to the LIMS.

IR Detection

Advanced infrared optical design increases sensitivity and because no gold reflection is used, the IR system is not susceptible to loss in signal due to dirty samples or compounds that strip gold coatings such as salts. The infrared is further improved by electronic “chopping” of the infrared source thereby increasing sensitivity and a significant reduction in the electronic signal to noise ratio. This means greater infrared cell stability thereby lowering the limit of detection. As the CS-1232 infrared is configured for either Carbon and Sulphur analysis, the electronic circuit identifies the unique properties of the infrared signal connected to it. The infrared detection is load balanced (reducing current load on power supply) and has many advanced features that filters noise, and any outside influencers.

Carbon and Sulphur Measure Flow System

The CS-1232 measure flow pulls the combusted gases from the furnace, through the anhydrone reagent system which removes any unwanted moisture from the combusted gases, through the infrared detection system and finally pushes the SO2 and CO2 to a flow controller where the flow rate is set to prescribed rate of flow. The CS-1232 uses three Oxygen purges to remove any unwanted atmospheric gases. As the pump is drawing gases through the combustion system, the Oxygen purge flow rate is greater than that of the pump. This means that an Oxygen rich combustion environment is always ensured. The CS-1232 allows the operator for easy access to reagent replenishment, measure flow control and furnace temperature via the front access door.

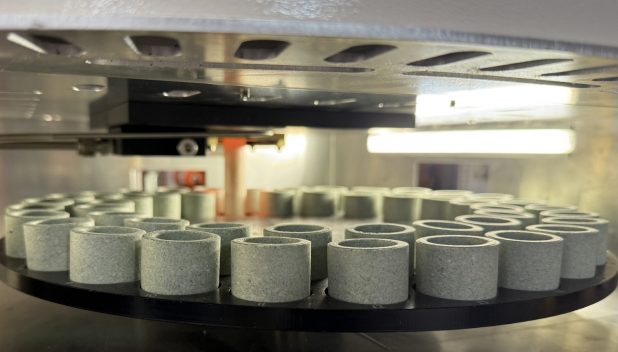

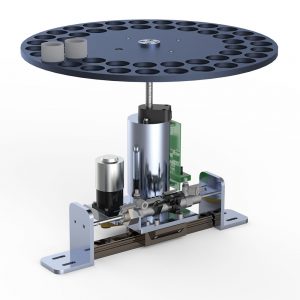

48 Position Sample Changer

The CS-1232 is designed with a 48 position sample changer that is fully integrated. As a result, the sample changer mechanism provides seamless loading and unloading of samples into and out of the combustion furnace. Every sample is unloaded and loaded back to its original position before the system advances to the next sample.

Analysis Software

The software has many powerful features that include the ability to linearise the IR cells. This means that the linear curve can be shifted to suit particular sample types or to work in the range you need to. The translates to better accuracy and reproducibility of your results.

The CS-1232 has advanced controls over how and when the combustion of the sample should stop. The ability to correctly and accurately determine the end of analysis is due to the precision of the infrared detection system.

The automated CS-1232 is designed for organic materials. The following applications are suitable for testing:

- Mineral ores

- Sulfide mineral deposit bearing ores

- Gold processing plants

- Copper processing plants

- Bauxite for aluminium production

- Cracking Catalysts

- Soils and Plants

- Cements

- Coking Coal for steel industry

- Coal for coal fired power plants

- Oils including diesels (hydrocarbons)

| Dimensions | 76cm (width) x 66cm (depth) x 93cm (height) |

| Weight | ~90 kg |

| Detection Method | Solid state Infrared Absorption for Carbon and Sulphur |

| Detection Range | Carbon cell to cover a range of 0.05% to 32% using 250mg samples. Low Sulphur cell to cover a range of 0.005% to 4.0% using 250 mg samples. High Sulphur cell to cover a range of 0.05% to 38.0% using 250 mg samples. The upper and lower detection limits can be extended by increasing or decreasing the sample weight depending upon combustion characteristics of the sample types |

| Accuracy | +/- 1% of the Element present |

| Analysis Time | 60 – 180 seconds (nominal) for coal samples |

| Sample Weights | Ores – 500 mg (nominal), Coal – 300 mg (nominal), Oils 100mg (nominal) |

| Furnace | Vertical resistance furnace with single cylindrical silicon carbide heating element |

| Temperature Range | Ambient to 1,400° C. Accuracy +/- 1° C |

| Drying Towers & Filters | Two Magnesium Perchlorate Drying Towers. One Glass Wool Filter |

| Gasses | Carrier Gas – Oxygen, 99.5% Purity, 275 kPa. Pneumatic Gas – Compressed Air, dry clean, 415 – 550 kPa. Incoming Gas Pressure Monitors |

| Computer | PC, Keyboard and Mouse, LED Monitor, Windows 10 Pro |

| Balance | Analytical grade 4 Place (0.1mg), Interfaced with PC |

| Crucibles | Non porous ceramic |

| Power | 115/240 VAC +/- 10%, Single Phase, 25 Amp (32 A outlet required) |