Thermocouple Wire

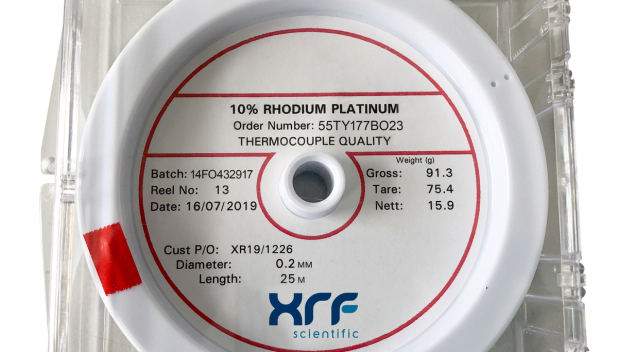

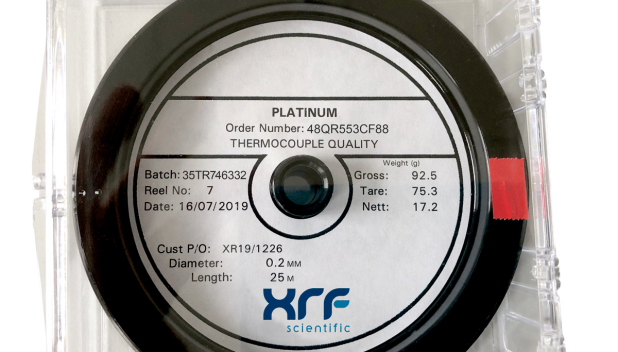

Based on truly collaborative design protocols with quality-assured suppliers and discerning end-users, XRF Scientific offers a range of tried-and-tested thermocouple-grade platinum wires for accurate temperature monitoring across broad temperature regimes.

All our semi-finished precious metal wiring solutions are fully traceable to a single source, enabling us to guarantee high-quality performance from alloy to alloy and across all specifications. This is critical for our platinum thermocouple wires which are designed to operate where conventional alloys cannot.

Types of Thermocouple Wires: S, B & R

Thermocouples are innovative cables composed of two dissimilar metal wires fused together at a single junction. The temperature-dependant conductivity/resistivity of these metals means that when the sensing end is exposed to heat, it produces a voltage differential that can be used to calculate the temperature. Various types of thermocouple wires are prescribed based on the atmosphere and temperature range of the sensing environment, the most common being type J (iron and constantan) and type K (nickel-chromium and nickel-alumel) thermocouples.

At XRF Scientific, we engineer high-performance thermocouple grade platinum wires for type S, type R, and type B thermocouples. These far outstrip the operating temperature capabilities of standard temperature sensing elements and can often be used bare in oxidizing atmospheres, or highly corrosive environments.

Browse the full specification tab on this page for in-depth information about each type of thermocouple wire that we offer. Or, contact a member of the XRF Scientific team today with any questions.

S wire consists of platinum and a Pt10Rh conductor, and is deployed in applications where temperatures reach 1600° C. It can be used bare, in a clean oxidizing atmosphere without any forced airflow.

R wire consists of platinum and a Pt13Rh conductor. It shares the characteristics of type S wire, but has a higher thermoelectric output.

B wire consists of Pt6Rh and a Pt30Rh. Predominately used in glass manufacturing processes, it can withstand temperatures of up to 1800° C.

The calibration is based on the ITS90 or IPTS68 standards.