Selecting the Right Crushing Equipment

Crushing equipment is central to a wide scope of sample preparation tasks, impacting all manner of workflows from the lab bench to the production line. Selecting the right crushing equipment for the job is subsequently critical. At XRF Scientific, we supply a wide range of laboratory crushers primarily used for elemental analysis. In this article, we will outline some of our crushing equipment to help you choose the best tool for the job.

The Basics of XRF Crushing Equipment

To accurately assess the x-ray fluorescent (XRF) properties of a dry, organic sample through XRF spectrometry, the sample must first be prepared with a fusion flux of either lithium metaborate (LiBO2), lithium tetraborate (Li2B4O7), or a mixture of the two with suitable oxidizing additives. The homogeneity of these mixtures can have a significant impact on results accuracy, which is why eutectic flux mixtures are prepared at varying ratios with distinct physiochemical structures. Following eutectic mixture selection, the dry analyte must be reduced to a suitable consistency for fusion using crushing equipment.

Laboratory crushing equipment typically pulverizes dry geological samples using mechanically agitating jaws or gyrating plates. The granulated material is typically then fed through to a divider to separate the analyte into samples of distinct weight profiles. Samples of complex mineralogical compositions may require multiple pulverizing methodologies to accurately prepare a sample for fusion flux.

Laboratory Jaw Crushing Equipment

The Orbis OM50 is a double-acting jaw laboratory crusher for sample preparation. Where conventional jaw crushing equipment reduces solid samples by gyrating a mechanical jaw against a fixed plate, this instrument uses dual-acting high chrome iron plates that gyrate at both the top and bottom for maximum crushing efficiency. It can hold samples of up to 10kg, and reduce samples by 35 times their original size. Higher capacity variants of the Orbis OM50 crusher are available for preparation of samples up to 15kg.

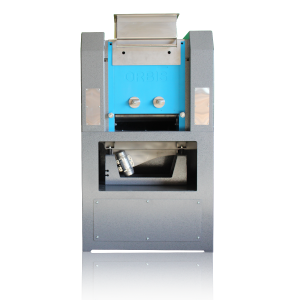

Sample Crusher & Divider

Crushing equipment can be integrated with dividers to streamline the sample preparation process. The Orbis OM50 combines the established crushing capacities of the product line with a vibrating feeder and a rotating sample divider, which rotates at pre-defined speeds to separate granulated solids in single or multiple splits. Linear sample dividers can also be equipped to Orbis crushing equipment, providing single-pass split of samples based on extremely precise sample weights.

Automated Crushing Equipment

Automated batch mills are critical for high throughput sample preparation environments where low intervention is key for meeting required laboratory workflows. Multiple automated crushing equipment systems are available from XRF Scientific, including a dual setup version of the OM100 smart RSD.

Crushing Equipment from XRF Scientific

XRF Scientific provides robust sample preparation solutions for low, medium, and high throughput environments, with unique solutions for application-specific requirements. Our range of crushing equipment features comprehensive innovations, from small footprint double-acting jaw crushers to intuitive automated systems.

Find out how a laboratory crusher works in more detail, or contact us for any more information about our crushing equipment.