xrFuse Electric Fusion Machines: Operating Principles

Since 2006, XRF Scientific has been spearheading the design and implementation of innovative fusion machines for cutting-edge sample preparation. At this time, the Phoenix range was already an industry-standard tool for inductively-coupled plasma (ICP) and X-ray fluorescence (XRF) sample preparation. Yet these markets needed a simple-to-use, automated electric fusion machine to suit the requirements of a broadening consumer base.

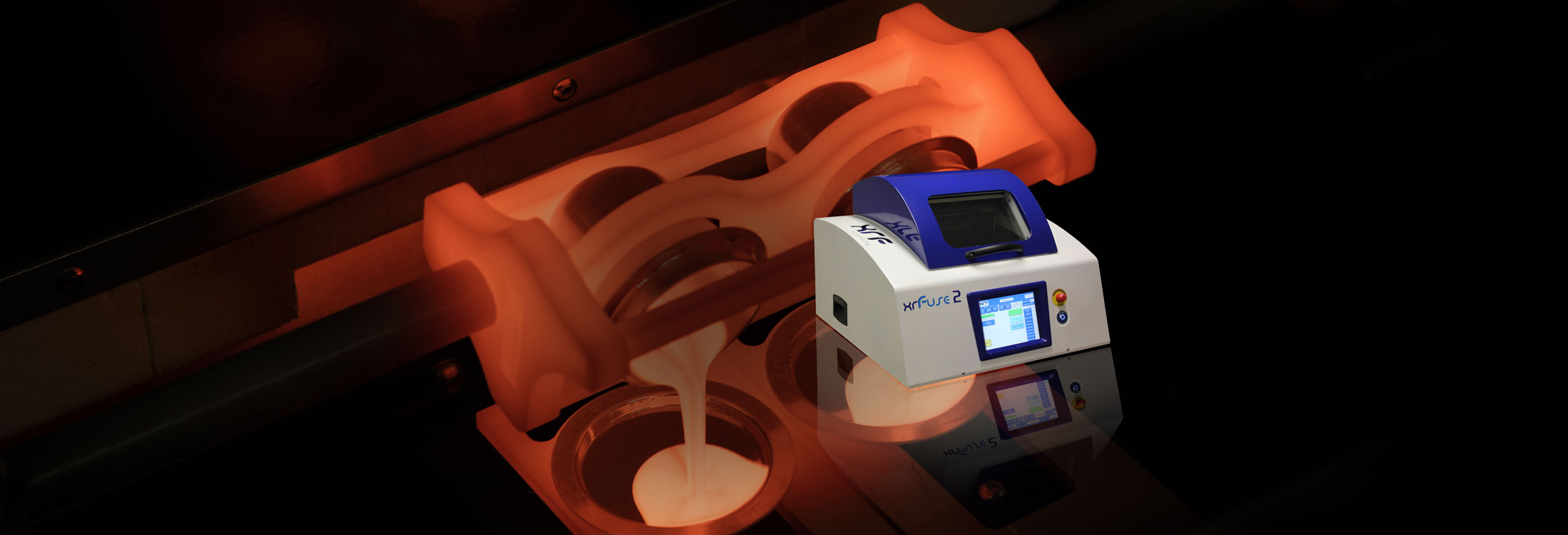

Our inaugural xrFuse electric fusion machine was released to a global market in 2013. Within a few short years, the product line has grown to cover three distinct instruments: the xrFuse 1, the xrFuse 2, and the xrFuse 6. In this post, we will outline the operating principles of the xrFuse range in more depth, providing a brief hardware and specifications analysis too.

How Do Electric Fusion Machines Work?

Electric fusion machines operate on the same fundamental principles as standard high-temperature furnaces, which use refractory elements to generate temperatures exceeding 1000°C (1832°F) within a carefully insulated heating chamber.

Silicon carbide (SiC) elements are used across the full xrFuse range, as the material properties are uniquely suited to the fusion environment. It is low density for a comparatively lightweight heating element construction, with comprehensive resistance to various corrosive agents and outstanding high-temperature characteristics (low thermal expansion, high thermal conductivity, excellent thermal shock resistance, etc.). the xrFuse 1 can generate peak temperatures of 1200°C (2192°F), while both the xrFuse 2 and xrFuse 6 can reach maximum peak temperatures of 1250°C (2282°F).

The walls of these electric fusion furnaces are embedded with high-performance ceramic fiberboard which stops heat from propagating into the aluminum shell, where it could damage electronics and result in poor process efficiency. Type R thermocouples are integrated into the entire xrFuse range to provide real-time temperature readings for accurate in situ process monitoring. Each one also comes equipped with a secondary, insulated thermostat for robust over-temperature protection.

However, each of these functions and pieces of hardware is available with a standard industrial or laboratory furnace. What distinguishes the xrFuse range of electric fusion furnaces from other processing ovens are the proprietary crucible cradles and mould holders within the heating chamber. These are constructed of extremely high-purity ceramic and are available with either one (xrFuse 1), two (xrFuse 2), or six (xrFuse 6) positions. The cradle of an electric fusion machine can be pre-programmed to rock for user-defined durations, speeds, and amplitudes. Once mechanical agitation has completed, samples can be left to stand for a selectable period. Even the pouring angle can be customized for finely-tailored fusion processes.

The primary difference between each member of the xrFuse product line is their throughput capabilities, owing to the number of positions available in the cradle:

- xrFuse 1: up to 4 beads per hour;

- xrFuse 2: up to 10 beads per hour;

- xrFuse 6: up to 30 beads per hour.

The advanced throughput of the xrFuse 6 electric fusion machine comes with a commensurable increase in the device’s workbench footprint, with the xrFuse 1 being the most economical in terms of space-saving capabilities.

Electric Fusion Machines from XRF Scientific

XRF Scientific is a world leader in the design and supply of electric fusion machines for industrial quality control and manufacturing process assurance worldwide. Recently, we have written a series of articles outlining the operating principles and capabilities of our broad product range. If you have found this post interesting, you might like to read our previous post Modutemp Shaking Electric Fusion Machine: Operating Principles.

If you have any questions about our gas or electric fusion machines, simply contact a member of the XRF Scientific team today.